Metal heat treatment furnace

Heat treatment is an indispensable process for the making of the metal components of cars, construction machines and manufacturing/industrial machines.

Murase offers facilities that help improve quality and save energy in making these products.

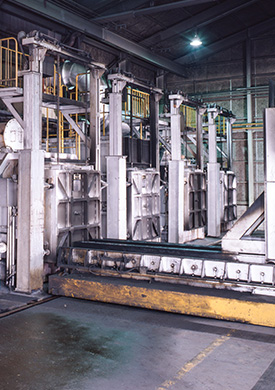

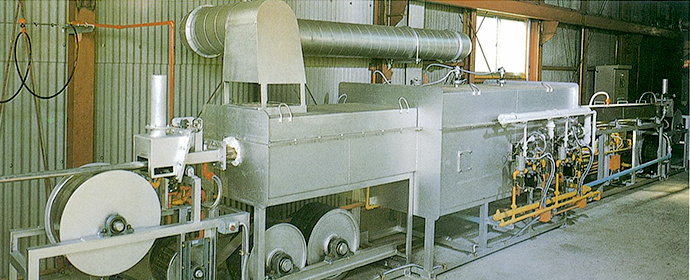

Roller hearth type hardening furnace

| Furnace type | Continuous hardening furnace |

|---|---|

| Application | Hardening |

| Treated products | Various cast steel products, cast iron components, etc. |

| Carrier method | Roller hearth type |

| Furnace interior atmosphere | Air |

| Treatment volume | 5,000kg/h(NET) |

| Dimensions | 700W*650L*1,900H(mm) |

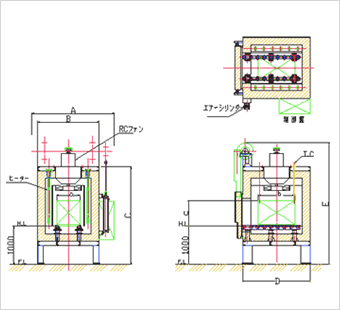

Batch-type tempering furnace

| Working temperature | Normal: 200 to 580℃ Maximum: 600℃ |

|---|---|

| Atmosphere | Air, nitrogen |

| Temperature distribution | Not higher/lower than ±5.5℃(unloaded, 560℃) Deviation from the central temperature of 9 measuring points within effective dimensions |

MET (electricity)

MGT (gas, oil)

Standard specifications

| Type | Effective dimensions | Approximate furnace dimensions | Treatment volume kg/grosscharge |

||||||

|---|---|---|---|---|---|---|---|---|---|

| a | b | c | A | B | C | D | E | ||

| 10N | 760 | 1220 | 760 | 2500 | 1800 | 2675 | 2100 | 3300 | 1000 |

| 6N | 610 | 950 | 610 | 2300 | 1600 | 2600 | 1760 | 3200 | 600 |

| 3N | 460 | 620 | 550 | 2000 | 1350 | 2450 | 1350 | 3080 | 300 |

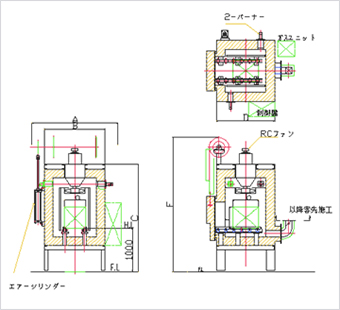

Fork charger type hardening furnace, tempering furnace

| Furnace type | Continuous hardening and tempering furnace |

|---|---|

| Application | Hardening and tempering |

| Treated products | Various cast steel products, cast iron components, etc. |

| Carrier method | Fork charger type |

| Furnace interior atmosphere | Air |

| Treatment volume | 2,000kg/CH(NET) |

| Dimensions | 1,200W*2,500L*7,000H(mm) |

For information about the fork-charger-type furnace, please see the “Murase's Technological Capability” page.

For information about the fork-charger-type furnace, please see the “Murase's Technological Capability” page.

Pit-type carburizing furnace

| Furnace type | Pit-type carburizing furnace |

|---|---|

| Application | Hardening |

| Treated products | Steel products |

Bright annealing furnace

| Furnace type | Stainless steel continuous bright annealing furnace | Furnace interior atmosphere | AX gas |

|---|---|---|---|

| Application | Bright annealing | Treatment volume | 50kg/h |

| Treated products | Stainless steel pipe | Dimensions | 130W*7,500L*90H(mm) |

| Carrier method | Stainless steel hoop type |

Walking beam type forging furnace

| Furnace type | Continuous forging furnace |

|---|---|

| Application | Forge heating |

| Treated products | Carbon steel round bar |

| Carrier method | Walking beam type |

| Furnace interior atmosphere | Air |

| Treatment volume | 2,300kg/h |

| Dimensions | 2,000W*6,000L*2,600H(mm) |

Trolley-type annealing furnace

| Furnace type | Trolley-type annealing furnace |

|---|---|

| Application | Annealing |

| Treated products | Cans and drums |

| Furnace interior atmosphere | Air |

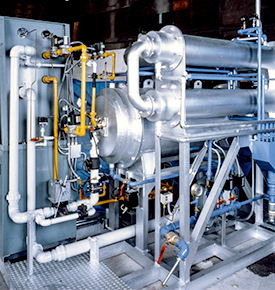

RX gas generator

| Equipment name | Endothermic atmospheric gas generator |

|---|---|

| Application | Anoxic, bright carburizing of carbon steel, etc. |

| Catalyst | Nickel catalyst |

| Reaction temperature | 850℃ |

| Generated gas volume | 30 to 100Nm3/h |

| Dimensions | 900W*1,800L*2,721H to 1,200W*3,000L*2,721H (mm) |

DX gas generator

| Equipment name | Exothermic atmospheric gas generator |

|---|---|

| Application | Anoxic, bright brazing of copper products, etc. |

| Generated gas volume | 30 to 400Nm3/h |

| Dimensions | 900W*2,100L*2,200H to 4,000W*2,300L*2,400H(mm) |